Electrical Setup

Wiring

Note

We do not give any safety warranties on the electrical wiring. All experiments and reproductions of our testbench are at your own risk.

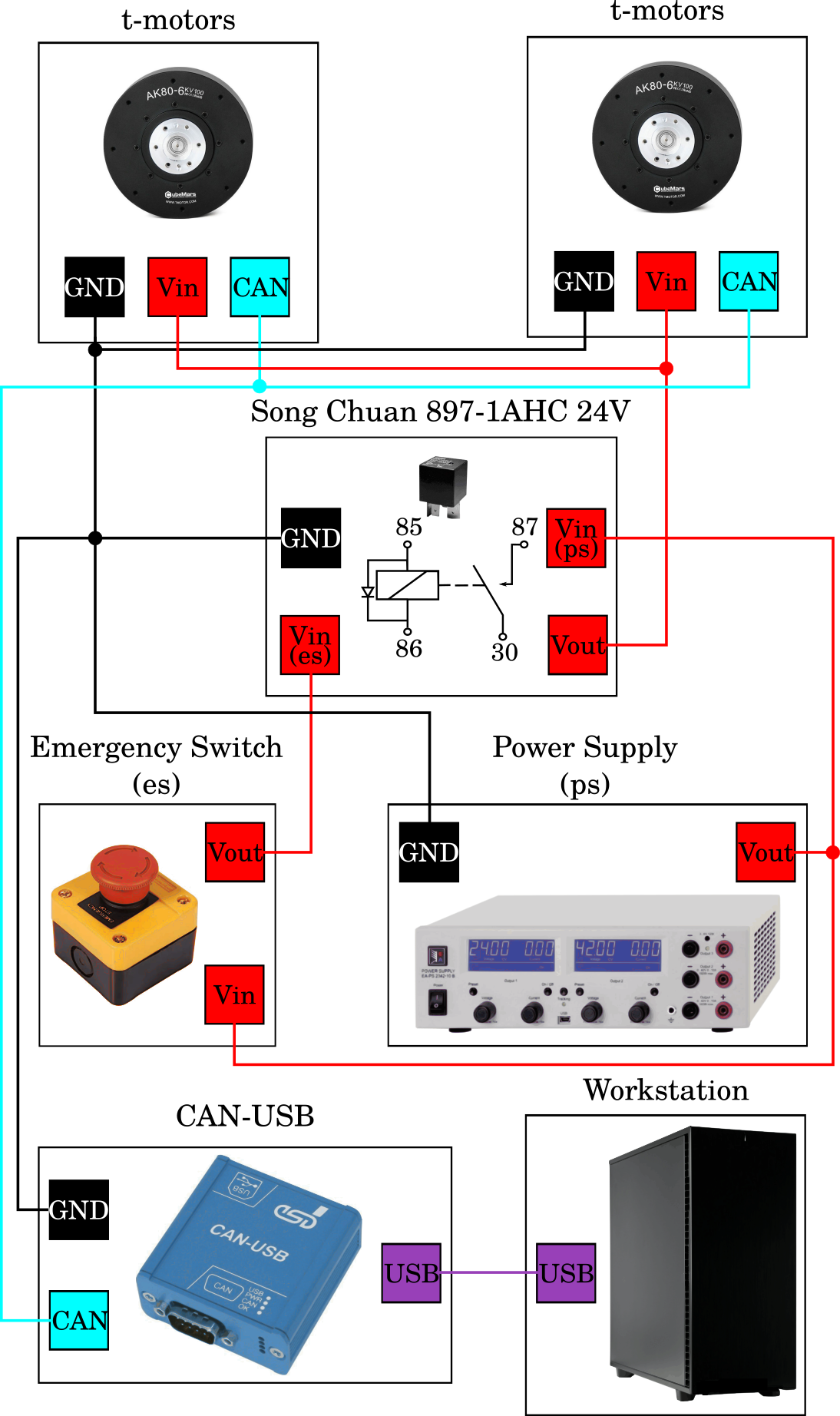

The wiring diagram below shows how the double pendulum testbench is set up. A main PC is connected to a motor controller board (CubeMars_AK_V1.1) mounted on the actuator (AK80-6 from T-Motor). The communication takes place on a CAN bus with a maximum signal frequency of 1Mbit/sec with the ‘classical’ CAN protocol. Furthermore, a USB to CAN interface is needed, if the main pc doesn’t have a PCI CAN card. Two different devices are used in our setup: the R-LINK module from T-Motor and the PCAN-USB adapter from PEAK systems. The former has CAN and UART connectors at the output, but only works with Windows. The latter only features CAN connection, but also works with Linux. The UART connector of the R-LINK module is useful to configure and calibrate the AK80-6.

The actuator requires an input voltage of \(\small{24\,V}\) and consumes up to \(\small{24\,A}\) under full load. A power supply that is able to deliver both and which is used in our test setup is the EA-PS 9032-40 from Elektro-Automatik. A capacitor filters the backEMF coming from the actuator and therefore protects the power supply from high voltage peaks. This wouldn’t be necessary if the actuator is powered from a battery pack, as in this case backEMF simply recharges the batteries. The capacitor we use is made of 10x single 2.7V-400 F capacitor cells connected in series resulting a total capacity of \(\small{40\,F}\) and is wired in parallel to the motor. A emergency stop button serves as additional safety measure. It disconnects the actuator from power supply and capacitor, if only the power supply gets disconnected the actuator will keep running with the energy stored in the capacitor.

Fig. 1: actuator = AK80-6, controller board = CubeMars_AK_V1.1, power supply = EA-PS 9032-40, capacitor = 10x 2.7V-400F cells connected in series, USB-CAN interfaces = R-LINK module and PCAN-USB adapter.

Steps for setting up the wiring

For setting up the CAN and power connections follow these steps:

Connect the emergency stop power cables to the power supply

Connect the capacitor in parallel to the power supply

Connect the emergency switch with power cables to the motors

Use the CAN cable to connect the motors with the CAN USB interface

Connect the CAN USB interface with the PC via USB

Note

Make sure that no cables hang in range of the motion of the double pendulum!

backEMF

The reverse current resulting from switching motor speeds from high to low is called backEMF (Electro Magnetic Force). When the motor speed decreases the motor works as a generator, which converts mechanical energy into electrical energy and hence the additional current needs some path to flow. The energy recycled back into the input power supply causes a voltage spike and potential risk. It is necessary to add enough input capacitance to absorb this energy. A sufficiently large input capacitance is important in the desgin of the electric curcuit. It is beneficial to have more bulk capacitance, but the disadvantages are increased cost and physical size.

If the power source were a perfect battery, then energy would flow back into the battery and be recycled. However, in our case the power source is a DC power supply. Especially power supplies with an inverse-polarity protection diode can only source current and cannot sink current, hence the only place the energy can go is into the bulk capacitor. The amount of energy stored in the bulk capacitor can be calculated with

where \(C\) is the capacitance and \(V\) is the voltage. In the case of a Simple Pendulum max. backEMF can be estimated from the kinetic energy of the pendulum

where \(M\) is the mass matrix and \(\dot{vect{q}}\) the angular velocities of the joints. The voltage across the capacitor increases as energy flows into it, so the capacitor should be sized accordingly to the specific application requirements. Nevertheless tuning a capacitor to the acceptable min. capacity is tricky, because it depends on many factors including:

External load

Capacitance of the power supply to source current

Motor braking method, output short brake or current polarity reversing brake.

Amount of parasitic inductance between power supply and motor system, which limits the current change rate from the power supply. The larger the input capacitance, the more stable the motor voltage and higher current can be quickly supplied.

The maximum supply voltage limit and acceptable voltage ripples

If the used capacitor is too small for your specific apllication it introduces the risk of burning the capacitor. The voltage rating for the bulk capacitors should be higher than the typical operating voltage and provide some safty margin. In our case we supply the AK80-6 with \(\small{24\,V}\), whereas the capacitor can take up to \(\small{27\,V}\). Therefore we have \(\small{3\,V}\) buffer, combined with a large capacity of \(\small{40\,F}\), we ensure that during voltage spikes the capacitor never gets fully charged. If you don’t want to buy a huge and expensive capacitor you may instead use a break resistor, which normally is cheaper to purchase. A guidance on this topic is provided here. One drawback using brake resistors is that they quickly heat up, if the motor frequently brakes and regenerates energy. Another option to prevent the bus voltage from spiking too high are resistive shunt regulators, e.g. like this one from polulu, but they can’t dissipate much power and high-power versions also get expensive.